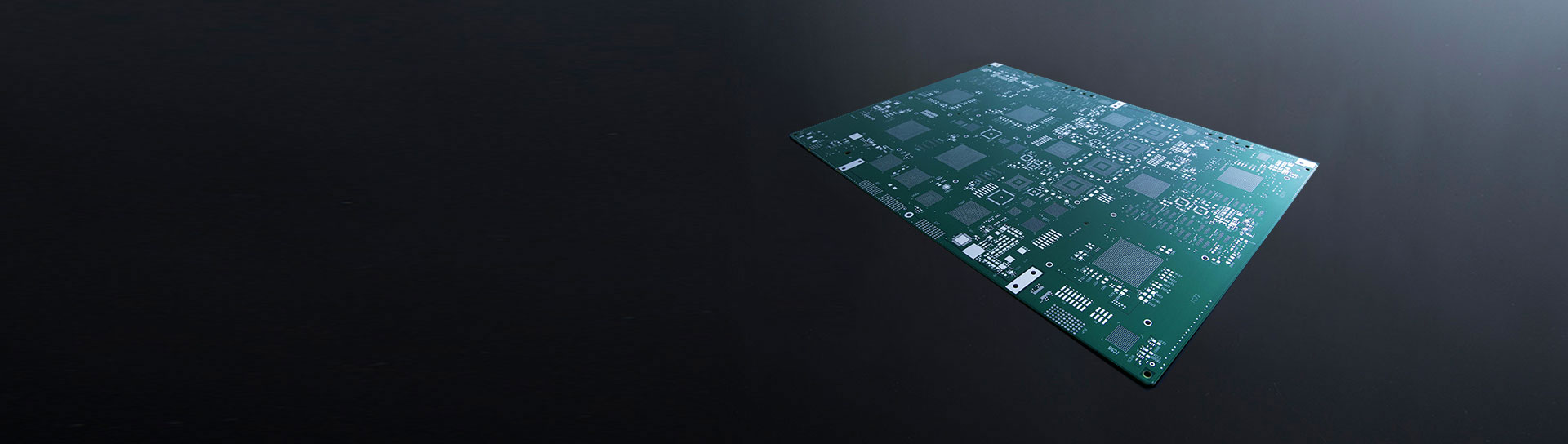

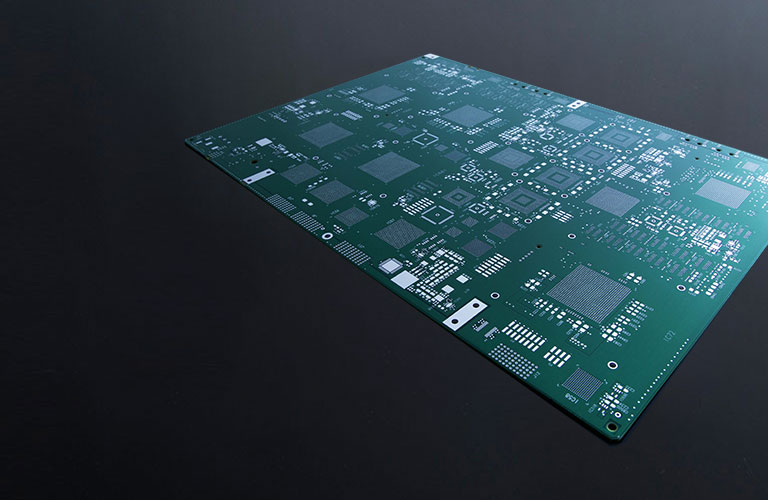

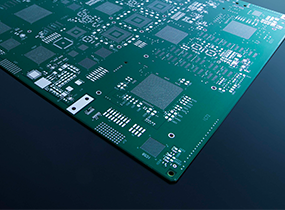

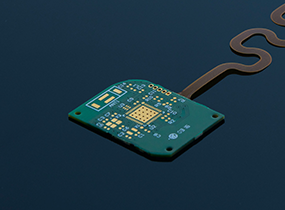

Multek can mass produce PCBs with up to 46 plus layers using high-speed/ultra low-loss materials for every market applications.

Our Multiple-Layer Rigid PCBs, including High Layer Count and High Density boards, offer a variety of features, including but not limited to:

• High-Density Interconnect with 1n1, 2n2, 3n3, & 4n4, ELIC or AnyLayer Buildups

• Advanced thermal management features such as embedded and attached COIN technology

• Thru-hole and µVia Technology,

• VIPPO, precision depth back-drill, and Copper Filled µVias

• OSP, ENIG, ENEPIG, Immersion Silver, Immersion Tin, and Selective Hard Au finishes

• Minimum Thru-Hole size < 0.15mm

To satisfy increasing product and sub-system requirements that span across all major consumer, telecom, datacom, commercial, automotive, medical, and industrial market segments.