-

Solutions

-

Product Finder

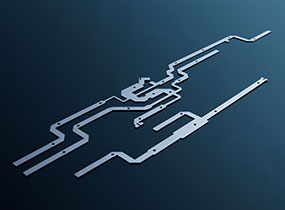

Electronic Circuit

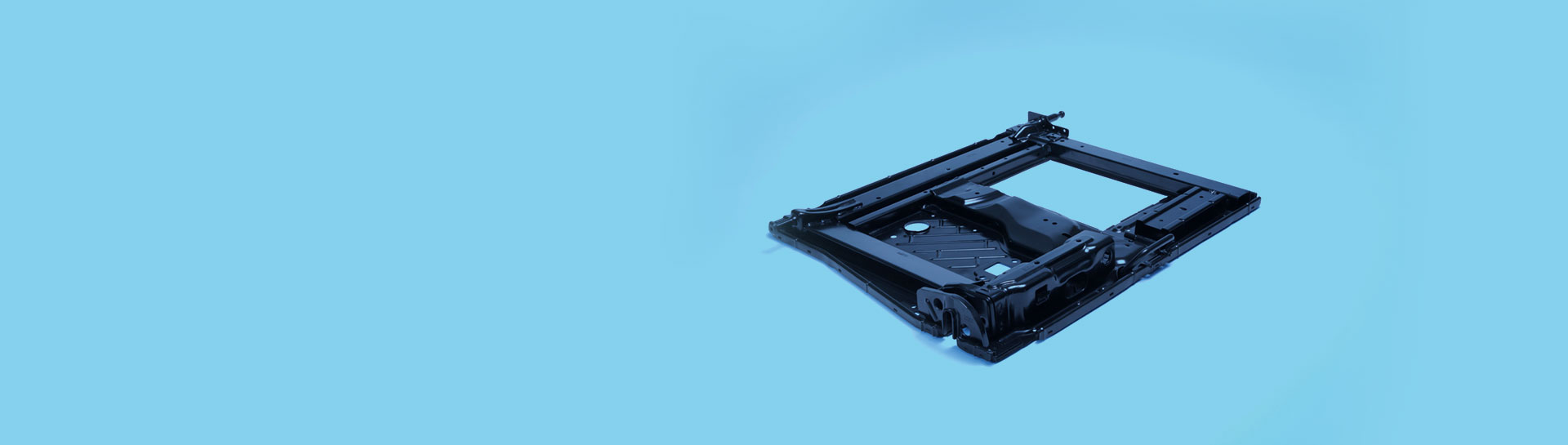

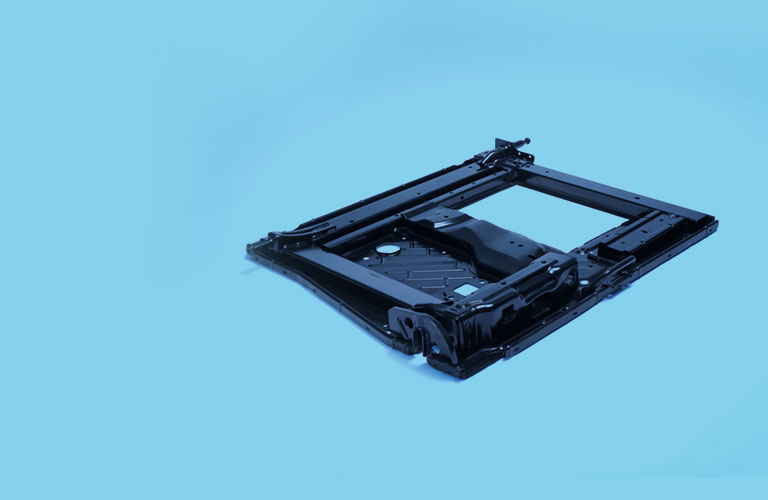

Photoelectric Display

Precision Manufacturing

-

Investor Relations

-

About Us

-

Join Us

-

Contact Us